Can a salt-spray test chamber really handle military-grade qualification?

Author:LINPIN Update Time:2025-08-28 Source:LINPINSalt-laden air is one of the most aggressive environments military hardware will ever face. From carrier decks to littoral launch sites, chloride ions attack metals, coatings, and electronics faster than almost any other stressor. If a fighter, frigate, or fire-control system can’t survive salt fog, it won’t survive the first deployment. That’s why salt-spray chambers are not just acceptable for defense work—they are mandatory.

-

Why defense programs demand salt-spray testing

• Structural integrity: Hull plates, aircraft skins, and weapon housings must resist pitting and exfoliation that can cut fatigue life in half.

• Electronics reliability: Radar arrays, comms boxes, and missile seekers are sealed to IP67, yet a single salt bridge across a PCB trace can blind a sensor.

• Coatings validation: MIL-PRF- coatings, anodize layers, and exotic PVD films are expensive; the chamber proves they’re worth the cost. -

How the test works—and which specs matter

A precision nozzle atomizes 5 % NaCl solution at 35 °C ± 2 °C while humidity stays above 95 %. That single sentence describes ASTM B117, but defense programs add teeth:

• GJB 150.11A (China)

• MIL-STD-810G, Method 509 (US)

• DEF-STAN 00-35 (UK)

• MIL-STD-810G, Method 509 (US)

• DEF-STAN 00-35 (UK)

These specs dictate cycle length (24 h to 1000 h +), orientation of test coupons, and post-test evaluation criteria such as red-rust percentage and coating adhesion loss.

-

Real-world applications

Avionics: Aluminum-lithium bulkheads and avionics bays are exposed to 96 h salt fog followed by functional checkout. Failures often show up as intermittent data-bus errors caused by fretting corrosion on connector pins.

Naval systems: Submarine hull weld coupons run 720 h cycles to validate new filler-metal chemistry; any pit deeper than 0.1 mm triggers a design review.

Missiles: Launch canisters spend years sealed but not perfectly dry. A 48 h salt-spray + 48 h high-humidity sequence identifies creeping corrosion on guidance rails that could jam a launch.

Electronics: LRU enclosures are tested with live bias applied; leakage-current monitors flag any ingress before it becomes a mission failure. -

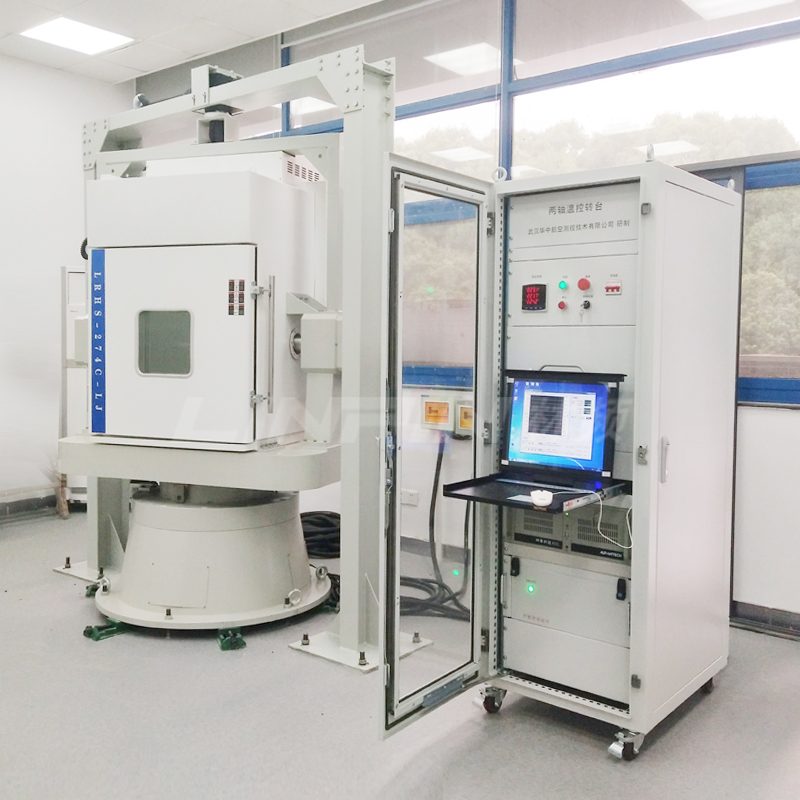

Choosing a chamber that meets defense expectations

• Certified traceability: Look for NIST-traceable salt concentration and temperature sensors, plus automated logging that meets 21 CFR Part 11 for data integrity.

• Corrosion-proof construction: Inner liner in PP or PVDF, external hardware in 316L stainless, and titanium heaters eliminate galvanic surprises.

• Programmable profiles: The controller must store multi-step cycles—salt fog → air-dry → wet standoff → repeat—without manual intervention.

• Large-volume options: Custom 10 m³ walk-in chambers accept full missile sections or rotorcraft avionics bays.

• Support for combined environments: Some specs (e.g., MIL-STD-810G 520.x) salt-fog + temperature/humidity/altitude, so modular add-ons save floor space.

Salt-spray chambers aren’t just “good enough” for military use—they’re the gatekeepers of readiness. When a destroyer spends months in the Arabian Gulf or an F-35 deploys to the Pacific, every alloy choice, gasket design, and conformal coat has already been proven in a cabinet no bigger than a walk-in closet. Pass that test, and the hardware is ready for the real thing.